Well, after 4 years and two moves, I’m finally back at this old beast. I’ve chronicled my previous work here, and where I left off was getting a sharp, swept trace, if I disconnected the +225V line from the upper deck where the Vertical circuits are. There are some leaky caps up there, and with them in the circuit, they pull a bunch of other things low, including the HV section (I don’t remember why, but it made sense at the time).

This is now a SEVENTY YEAR OLD machine, and given that every Black Beauty & Bumble Bee capacitor I’ve come across so far has been the cause of trouble, I think the best course of action is simply to replace all of them.

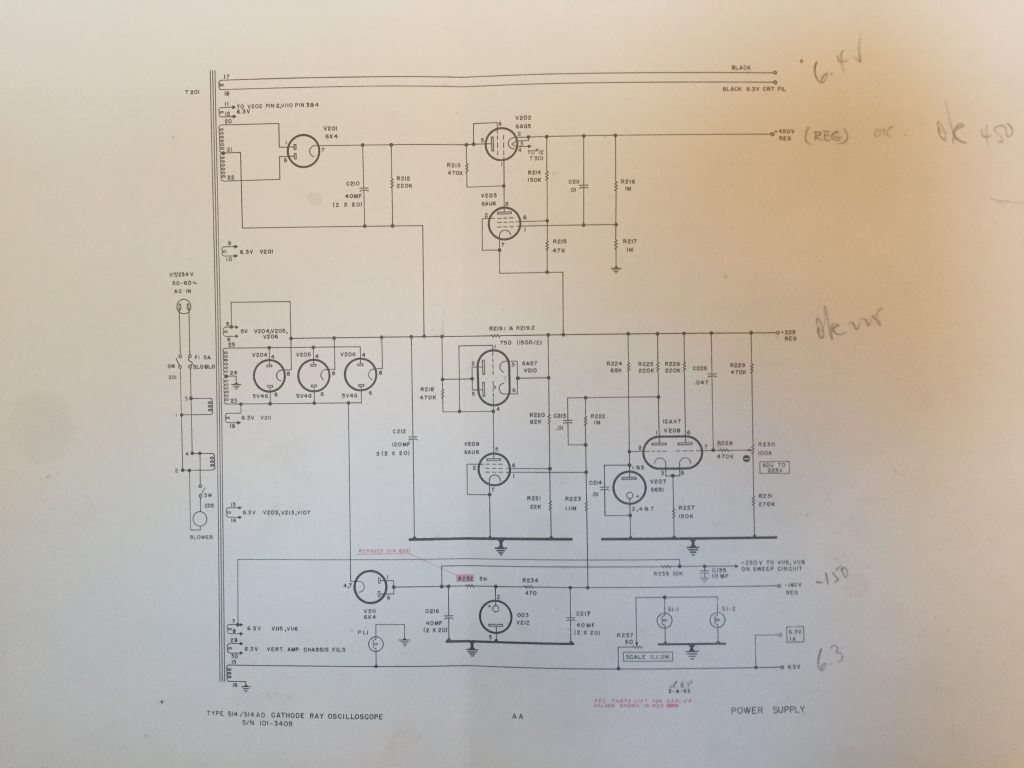

After changing / checking / reforming every cap on the upper deck, I still was having problems with the +225V supply, so I turned my attention back to the regulator. It turned out that the series pass tube wasn’t working: All of the current was flowing through the bypass resistors, so the voltage level was based only on the current. I confirmed this by pulling the Series pass tube (6AS7), and noted no change in the behavior. Working back from the voltage trim-pot, I discovered that the 12AX7 comparator wasn’t working properly. The socket needed some cleaning, and then the whole thing locked right up at 225V.

So, it “works”!

Here it is triggering at 10MHz

Issues:

- Sweep linearity: going to change out the bumblebee caps in the timing circuit to see if that helps.

- Sweep magnifier all sorts of weird.

- Interplay between vertical position & vertical attenuation controls: need to look into this more – The ‘Vertical Attenuation’ control affects the vertical position of the trace. Not sure if this is supposed to happen or not, but I’d think not.

- Change in intensity yields change in trace width: It seems to affect the horizontal trace width only, and happens in a counter-intuitive way; the trace gets wider when the image gets brighter.

- Calibrator has an overshooting leading edge.

Sweep Linearity:

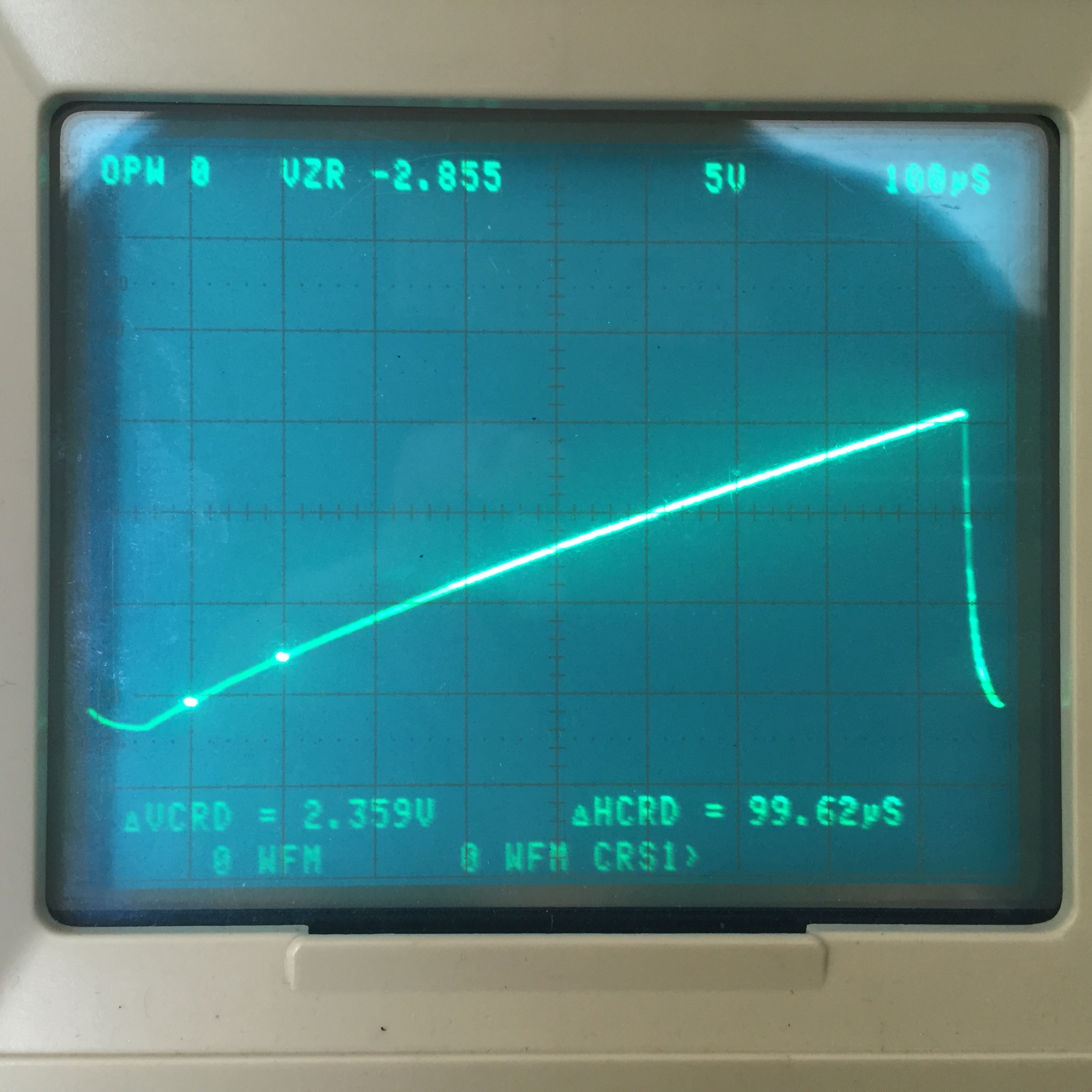

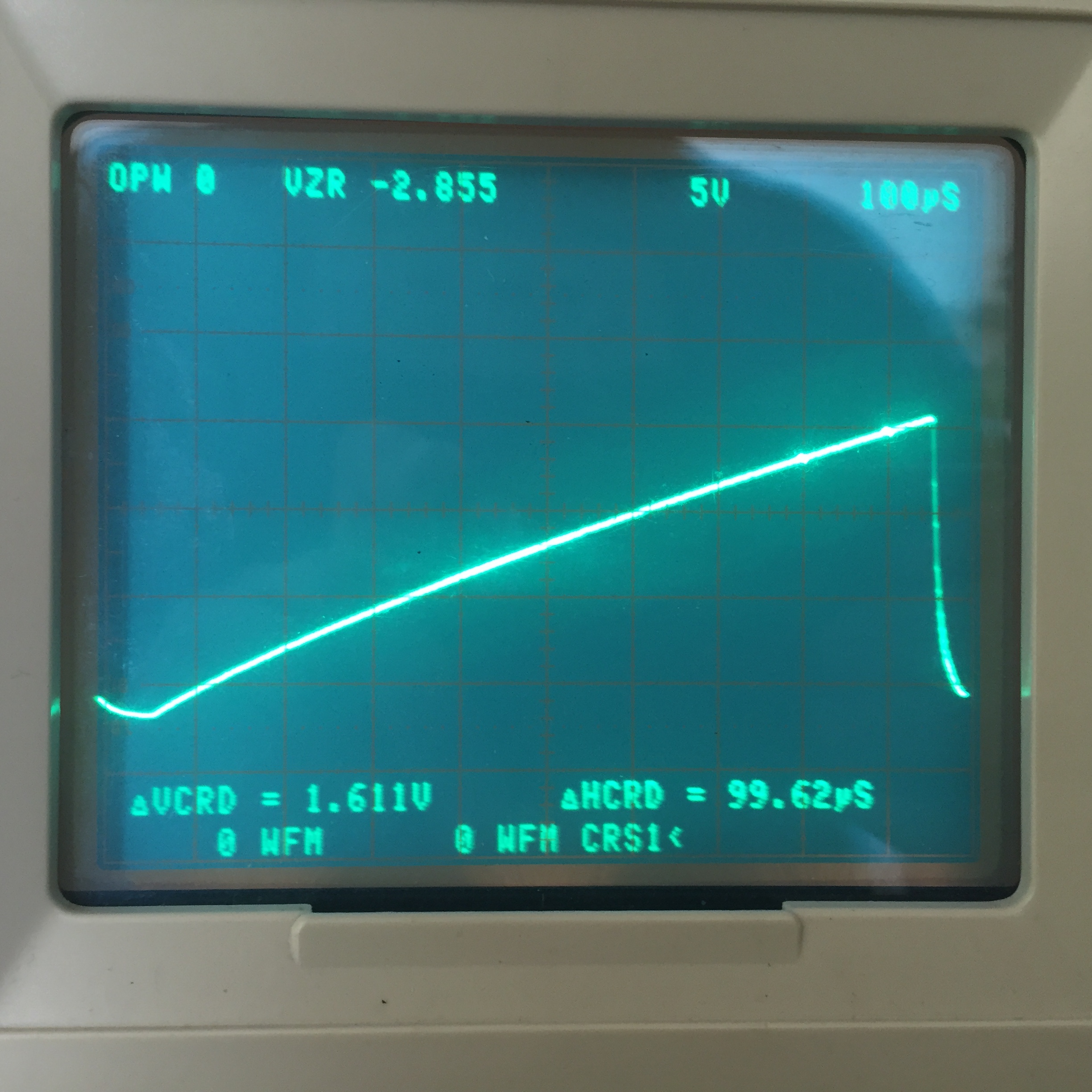

note the difference in slope between the beginning of the sweep waveform, and the end of it. Notice the difference in the slope between the start and the end of the sweep in the traces below. The worst of it was on the 100uS per division setting, and a new cap helped.

Sweep Magnifier:

C124, a .1uF bumblebee was the culprit. Replacing that, and restuffing C126, an electrolytic, solved the problem.

Calibrator

The problem turned out to be, what pretty much every other problem in this scope was – a bad bumblebee capacitor. I’m just replacing all of them as I work across the scope; I replaced this one in passing, and the problem was gone on the next power up.

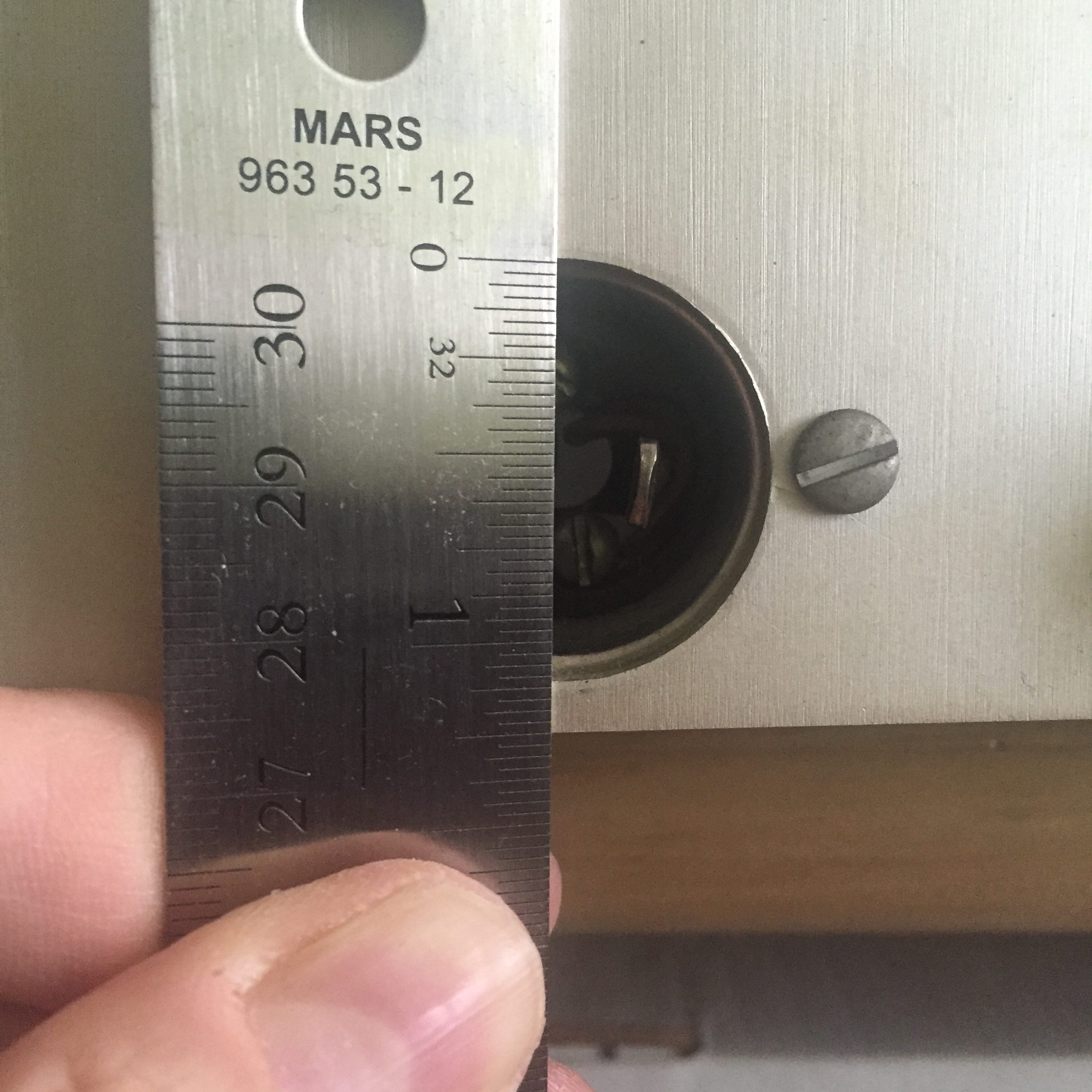

AC Socket

I’ve never seen one quite like this before. It’s recessed, as are many of the later tektronix sockets, but there’s no ground pins, so the blades are centered.

– Screw spacing = 1 1/2″

– Chassis hole diameter = 1 1/8″

– Socket inner diameter = 1″

According to some folks on the tekscopes group, these were not grounded, but rather accepted common extension cords of the time – searching used General Electric extension cords on eBay yields some good hits.

This picture from the 1952 catalog confirms their shape, and that the socket was not grounded. A member on the Tekscopes group says the manual instructs the user to ground the instrument via the front panel banana jack, but I couldn’t find reference to that.

If I wanted to replace it with a grounded alternative, I’ve got a few options:

- an IEC cord – Would require some filing of the frame hole to fit, and may require some bodging of the steel case as well.

- a powercon connector. may fit unaltered, at an angle, but might interfere with the back case, or require it to be modified.

- midget twist-lock – 2 prong will fit, mostly unaltered, but the 3 pin would require opening the hole in the chassis, and re-drilling the mounting holes.

Here’s the drawing of the 3 pole midget twist-lock. I think this is the best compromise, as it doesn’t involve any adapter plates or square holes – just enlarging some already round holes by 1/8″. Incidentally, note the original date on that drawing. I appreciate that there’s a 55 year old drawing on a manufacturer’s site that’s still a current reference.